Need any help or advice?+44 (0)1782 450300

Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

GlassCast 50 PLUS Super Deep Cast Epoxy Resin - 5kg Kit

- GlassCast®

- 5/5 Average rating

GlassCast 50 PLUS is a new 'extra deep' crystal clear, two-part epoxy resin system for really deep pours!

Designed for deep section castings of 50mm, with a slow cure to allow deep single pours with a slower, longer curing time. This resin is ideal for projects like large resin river tables, large dried flower encapsulation, and thick castings for projects like paperweights and lamp bases. The recommended pour thickness for GlassCast 50 PLUS is 50mm and it can be layered to achieve a greater depth.

GlassCast 50 can be left clear or pigmented with a wide range of pigments and metallic effects and is our recommended resin for river tables, deep castings, 3D resin art, extra large scale blanks for turning and more.

Sold as a kit, including resin and hardener. Available in 5kg, 15kg and 30kg kit sizes.

PRODUCT VERSIONS

Kit Size

AVAILABILITY:More than 5 availablefor immediate shipping

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

GlassCast 50 PLUS is a special new 'extra deep' version of the GlassCast casting resin designed for REALLY deep pours up to 50mm in a single pour (80mm into a thin walled mould) ideal for river tables, wedding flower encapsulation, and super-chunky castings such as resin lamp bases.

GlassCast 50 PLUS is still water-clear, self-degasses to produce bubble-free castings, and has amazing UV stability like GlassCast 50 but is even slower curing, allowing huge pours like 50mm deep river tables to be undertaken in a single pour. However, this does mean much longer curing times so please read below to see if GlassCast 50 or GlassCast 50 PLUS would be best for your project.

GlassCast 50 PLUS Advantages

- 80mm thick castings in a single pour when using thin walled silicone moulds

- 50mm layers into wood for deep pour river tables

- Highly UV stable - GlassCast is best-in-class

- Natural air bubble release - almost zero trapped air without degassing

- Highly machinable - great for turning, shaping and polishing

- 100% solids - zero shrinkage

- No odour - VOC free

Should I choose GlassCast 50, or 50 PLUS for my project?

All epoxy casting resins have a maximum depth which they can be poured at before they are at risk of overheating which can cause discolouration and distortion during the cure. When choosing between GlassCast 50 and 50 PLUS for your project, it's important to consider what the maximum depth of your pour is, and whether it would be better done in one pour or two.

For GlassCast 50, the maximum depth per pour when pouring into insulating materials (like a wooden river table) is 25mm. For GlassCast 50 PLUS, this maximum depth is 50mm. However, in order to achieve the 50mm maximum depth, GlassCast 50 PLUS cures much more slowly and will take a full 7 days to cure at normal room temperature.

If you only need to pour a maximum of 25mm depth then - unless you're working in unavoidably warm conditions - it would be better to use GlassCast 50.

If you need to pour 50mm in total then it might still be better to do this in two separate pours. The advantage to two separate pours can be a reduced overall curing time; 3 days using two pours of GlassCast 50 vs 7 days using one pour of GlassCast 50 PLUS, and also pouring in two layers reduces the 'stakes' should something go wrong (such as a leak) of each pour.

GlassCast 50 PLUS Recommended Uses

GlassCast 50 PLUS is all about those REALLY deep pours and big projects, any situation where you need a bubble-free, water-clear, odourless casting resin to use alongside wood, inclusions or embedments.

The most popular applications for GlassCast 50 PLUS are deep pour epoxy river tables, cast in a single pour and the preservation of wedding flowers where the shape of the flowers calls for a very deep section of resin.

- Deep river tables - up to 50mm in a single pour

- Preservation of wedding flowers

- Very thick castings such as resin lamp bases

Further Information

Ambient Temperature and Pour Depth

The GlassCast range of resins, in common with all epoxies, generate heat as part of the curing process. The amount of time the mixed resin can spend in the pot, as well as the maximum depth it can be poured at, will vary depending on the ambient temperature.

For best results, we recommend working in a consistent room temperature of 20°C. GlassCast 50 PLUS can be used in temperatures from 17 to 29°C but higher temperatures will reduce the maximum pour-depth of the resin significantly, as shown in the table below.

| Ambient Temperature | 17°C (minimum) | 20°C (recommended) | 23°C | 25°C | 30°C (maximum) |

|---|---|---|---|---|---|

| Maximum Pour Depth | 80mm | 50mm | 50mm | 30mm | 25mm |

| Initial Cure Time | 9 days | 7 days | 5 days | 4 days |

For deeper pours, up to 80mm the addition of a fan positioned to provide airflow over the resin can be used to remove heat as it cures!

How to Use

GlassCast 50 PLUS has been developed for professional users to produce the best results possible. It is not a 'craft' product and not intended for children. Before purchase, storage or use you must read the safety and technical data. Having said that, GlassCast 50 is very easy-to-use and delivers fantastic results under a wide range of conditions.

GlassCast 50 is sold as a kit which includes both the resin and hardener. Take a look at our Resin Calculator to work out how much GlassCast you need for your project. When you are ready to pour, measure the resin and hardener at the correct ratio and mix thoroughly. Add any pigments or effects and then pour the resin - no more than the recommended depth - into your mould, cavity or wherever you're using it. The resin will reach initial cure in around 7 days.

Download the Technical Datasheet from the 'Downloads' tab for full details on correct measuring, mixing and use of the product.

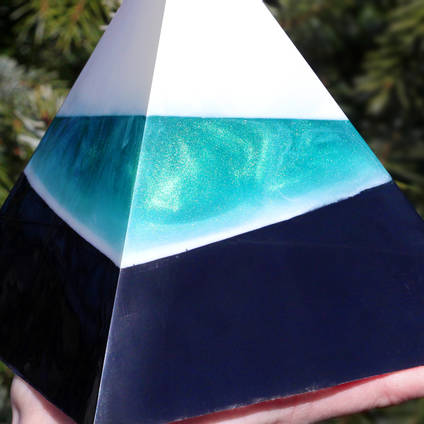

Getting More Creative - Pigments, Tints and Metallics

Although GlassCast 10 is often used completely clear it is also compatible with our complete range of tints, solid-colour pigments and metallic-effect powders. Many other colours and powders can be added too but be sure to conduct a test to ensure compatibility.

- Metallic effect SHIMR powders for swirling, sparkling colour

- CULR epoxy colour pigments for see-through to opaque in a wide range of colours

- Pinata alcohol inks for vibrant, translucent colour

The advantages to a single pour using GlassCast 50 PLUS are that you only have one pour to think about (you don't need to worry about when to do the second pour), and you can blend pigments and effects in one and have that effect running all the way through the resin.

GlassCast 50 PLUS is a special new 'extra deep' version of the GlassCast casting resin designed for REALLY deep pours up to 50mm in a single pour (80mm into a thin walled mould) ideal for river tables, wedding flower encapsulation, and super-chunky castings such as resin lamp bases.

GlassCast 50 PLUS is still water-clear, self-degasses to produce bubble-free castings, and has amazing UV stability like GlassCast 50 but is even slower curing, allowing huge pours like 50mm deep river tables to be undertaken in a single pour. However, this does mean much longer curing times so please read below to see if GlassCast 50 or GlassCast 50 PLUS would be best for your project.

GlassCast 50 PLUS Advantages

- 80mm thick castings in a single pour when using thin walled silicone moulds

- 50mm layers into wood for deep pour river tables

- Highly UV stable - GlassCast is best-in-class

- Natural air bubble release - almost zero trapped air without degassing

- Highly machinable - great for turning, shaping and polishing

- 100% solids - zero shrinkage

- No odour - VOC free

Should I choose GlassCast 50, or 50 PLUS for my project?

All epoxy casting resins have a maximum depth which they can be poured at before they are at risk of overheating which can cause discolouration and distortion during the cure. When choosing between GlassCast 50 and 50 PLUS for your project, it's important to consider what the maximum depth of your pour is, and whether it would be better done in one pour or two.

For GlassCast 50, the maximum depth per pour when pouring into insulating materials (like a wooden river table) is 25mm. For GlassCast 50 PLUS, this maximum depth is 50mm. However, in order to achieve the 50mm maximum depth, GlassCast 50 PLUS cures much more slowly and will take a full 7 days to cure at normal room temperature.

If you only need to pour a maximum of 25mm depth then - unless you're working in unavoidably warm conditions - it would be better to use GlassCast 50.

If you need to pour 50mm in total then it might still be better to do this in two separate pours. The advantage to two separate pours can be a reduced overall curing time; 3 days using two pours of GlassCast 50 vs 7 days using one pour of GlassCast 50 PLUS, and also pouring in two layers reduces the 'stakes' should something go wrong (such as a leak) of each pour.

GlassCast 50 PLUS Recommended Uses

GlassCast 50 PLUS is all about those REALLY deep pours and big projects, any situation where you need a bubble-free, water-clear, odourless casting resin to use alongside wood, inclusions or embedments.

The most popular applications for GlassCast 50 PLUS are deep pour epoxy river tables, cast in a single pour and the preservation of wedding flowers where the shape of the flowers calls for a very deep section of resin.

- Deep river tables - up to 50mm in a single pour

- Preservation of wedding flowers

- Very thick castings such as resin lamp bases

Further Information

Ambient Temperature and Pour Depth

The GlassCast range of resins, in common with all epoxies, generate heat as part of the curing process. The amount of time the mixed resin can spend in the pot, as well as the maximum depth it can be poured at, will vary depending on the ambient temperature.

For best results, we recommend working in a consistent room temperature of 20°C. GlassCast 50 PLUS can be used in temperatures from 17 to 29°C but higher temperatures will reduce the maximum pour-depth of the resin significantly, as shown in the table below.

| Ambient Temperature | 17°C (minimum) | 20°C (recommended) | 23°C | 25°C | 30°C (maximum) |

|---|---|---|---|---|---|

| Maximum Pour Depth | 80mm | 50mm | 50mm | 30mm | 25mm |

| Initial Cure Time | 9 days | 7 days | 5 days | 4 days |

For deeper pours, up to 80mm the addition of a fan positioned to provide airflow over the resin can be used to remove heat as it cures!

How to Use

GlassCast 50 PLUS has been developed for professional users to produce the best results possible. It is not a 'craft' product and not intended for children. Before purchase, storage or use you must read the safety and technical data. Having said that, GlassCast 50 is very easy-to-use and delivers fantastic results under a wide range of conditions.

GlassCast 50 is sold as a kit which includes both the resin and hardener. Take a look at our Resin Calculator to work out how much GlassCast you need for your project. When you are ready to pour, measure the resin and hardener at the correct ratio and mix thoroughly. Add any pigments or effects and then pour the resin - no more than the recommended depth - into your mould, cavity or wherever you're using it. The resin will reach initial cure in around 7 days.

Download the Technical Datasheet from the 'Downloads' tab for full details on correct measuring, mixing and use of the product.

Getting More Creative - Pigments, Tints and Metallics

Although GlassCast 10 is often used completely clear it is also compatible with our complete range of tints, solid-colour pigments and metallic-effect powders. Many other colours and powders can be added too but be sure to conduct a test to ensure compatibility.

- Metallic effect SHIMR powders for swirling, sparkling colour

- CULR epoxy colour pigments for see-through to opaque in a wide range of colours

- Pinata alcohol inks for vibrant, translucent colour

The advantages to a single pour using GlassCast 50 PLUS are that you only have one pour to think about (you don't need to worry about when to do the second pour), and you can blend pigments and effects in one and have that effect running all the way through the resin.

The GlassCast range of products are not designed for permanent outdoor use. Although the GlassCast resins have a very high level of UV resistance, the very high levels of UV exposure and the variety of inclement weather and environmental conditions experienced mean that the resin would degrade if permanently used outdoors.

Certainly, we can sell the resin and hardener separately if you need extra of either one one its own. Although not listed on the website we can do this over the phone or you can email us and we can send you an invoice with the correct amounts on it. The hardener for each of the GlassCast products is unique for that product. Using hardeners from other resin systems will cause serious curing issues or it may not cure at all.

Any mild soap and detergents will be fine for cleaning GlassCast Resin. Try to avoid strong acids or bases or neat cleaning products as it is possible they may dull the surface finish.

Hi Nicole, this would slightly depend on how you'll be making up that total depth. Generally speaking, flower preservation castings are done in at least 2 pours often more. At the very least, the first pour is usually used to provide a clear 'shelf' on which to position the flow so that it appears suspended in the final casting.

If you're doing multiple pours on a casting that will be a total of 7cm thick then it will probably mean that no single pour exceeds the 50mm maximum (per pour) for GlassCast 50 (when pouring into a mould) and so you could use GlassCast 50.

If you wanted to do the whole depth (50mm or more) in a single pour however then you would need to choose the GlassCast 50 PLUS. 50 PLUS allows you to cast up to 100mm (into a mould) in a single pour with a lower risk of the resin over-heating during its cure. This makes it great for big/deep castings and would make it a good choice for 50-70mm flower preservations but the trade off is that it does mean that it takes a lot longer to cure; around 7 days compared to 48hrs for GlassCast 50.

The pot life is largely effected by the temperature and volume (especially thickness) of the mixed quantity. At 23°C 500g in a section of 90mm will have around ~17 hours of pot life.

GlassCast 50+, along with the other resins in the GlassCast range, although not recommended for high temperature applications has been found to resist the heat from hot objects, such as coffee cups, very well and in a comparable way to other all resins on the market that we have tested including many that specifically claim to be ‘high-temperature’.

In common with all epoxy resins that we have tested, following a full 7 day cure, a very subtle ring can be left by leaving an extremely hot cup to stand on the surface of the resin, this mark is slight can usually only be seen if the surface reflection is inspected closely. Customers who use this resin for drinks coasters report that the marking is almost un-noticeable in practical applications and continue to use GlassCast 3 commercially for coaster applications.

However, it should be noted that we wouldn’t recommend GlassCast 50+ for coasters based on their thickness; 50+ is a deep casting resin and very slow curing; its likely that when poured at coaster thicknesses, the cure time could exceed 7-10 days so would be impractical. GlassCast10 is the more often used option for coasters.

Although we believe that our resin performs very well in coaster applications we recommend that customers do their own tests to ensure that they are happy that the resin performs to their requirements, to the best of our knowledge there are no other readily available clear resin systems that have distinctly better performance.

ASK YOUR OWN QUESTION

Customer Product Reviews for GlassCast 50 PLUS

I just wanted to say how absolutely amazed I am at the GlassCast 50 plus. I have just made a vase that started out as a root ball. I do not have a pressure pot so was concerned that I would end up with lots of bubbles etc but there were virtually none, your product does everything it should.

Amazing resin. Recently used 50 plus on a commission that needed a very deep pour, this product didn't disappoint. My go to resin!

Great resin that opens up loads of possibilities for deeper pours. Having made a few river tables, its amazing to be able to do them in a single pour and still get fantastic results. Absolutely love it!

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

Related Products

Customers Also Bought

Related Products

Customers Also Bought

100% SECURE

PAYMENT METHODS

GlassCast Resin is a trading name of Easy Composites Ltd, registered in England, 7486797. All content copyright (C) Easy Composites Ltd, 2022. All rights reserved.